Custom Order process

Follow us through our custom engagement ring process:

Most customers already have an idea of what they want but are just unable to find it, so they order a custom-made ring instead. Purchasing a ring to wear for a lifetime can be tricky when the buyer may have never worn a piece of jewelry. We are not only jewelry designers, but our experience gives us the edge in knowing what customers want in terms of durability, wear-ability, and comfort. Follow Ben’s vision for the process to transform his ideas into a dazzling engagement ring for his future fiancé.

Discussing your idea:

Ben knew that he wanted a unique ring that was different from the traditional solitaire. He also knew that his future fiancé loved sapphires. Julio gave him a quick lesson on the 4 C’s (Cut, Clarity, Carat, and Color). Ben brought some basic design ideas with him but wanted Julio to help him create that one-of-a-kind piece. Julio showed him metal options (platinum, 18kt white/yellow/rose gold, 14kt white/yellow/rose gold, and palladium), a few stones (diamond and sapphire), then sketched out quick designs to show Ben. They also discussed details such as the wedding band needing to fit or stack with a band, potential allergies to metal, and durability. Ben decided on a beautiful diamond with two side sapphires and a design that he thought was the best fit for his future fiancé.

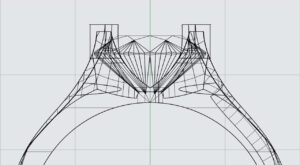

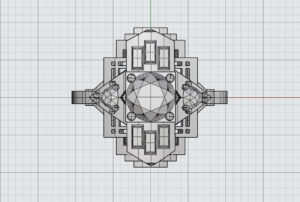

3D Design:

Ben’s idea was then transformed into a 3D image using special computer aided design technology showing how the stones would look together in the requested ring size. (Review of the 3D design can be done in person or easily over a zoom meeting.) Ben loved the ring but decided to alter the design slightly by requesting a tapered band. The placement of the diamond and sapphires were just as he envisioned. Julio easily made the changes to the design.

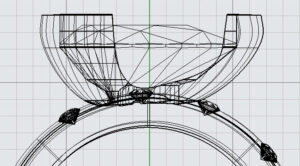

Model:

Ben stopped by the store to see the 3D model brought to life in a plastic resin model of the ring. The model was in the actual size and shape of his future ring. This was the final inspection that Ben was to have before the casting process and he loved the design. He gave the necessary approval to begin the ring casting process.

Setting:

The metal is poured, set, sanded and polished. The gems are then dropped into place. Ben’s future fiancé’s ring is now ready.

Pick Up:

Ben arrived at the store to pick up his future fiancé’s ring. If Ben doesn’t get the size quite right, that’s ok; we’ll happily re-size the ring. Also, we have an exchange policy that guarantees your fiancé’s happiness!

Cancellation policy:

If a customer requires an edit to a ring or bracelet after the piece has been cast or set, there will be a fee included. If a customer cancels a piece after it has been cast, there will be a fee included. We are charged by our manufacturers for the final piece in addition to their hours worked, so we end up paying out of pocket when a piece is canceled after those stages are complete. If a customer cancels a piece after custom work has been done, a cancellation fee of 30% of the cost of the piece will be charged. Thank you for understanding.